Blog

E6000 vs Shoe Goo: Are They The Same?

E6000 vs Shoe Goo, what should you pick if your favorite shoes encounter unexpected problems?

If you have some time and craftsmanship for a DIY project, it’s time to look deeper into the function and the difference between these well-known adhesives. So, you’ll know which would be the best choice for you!

Contents

Are Shoe Goo And E6000 The Same?

Although E6000 and Shoe Goo come from the same brand, they belong to two separate lines with different uses.

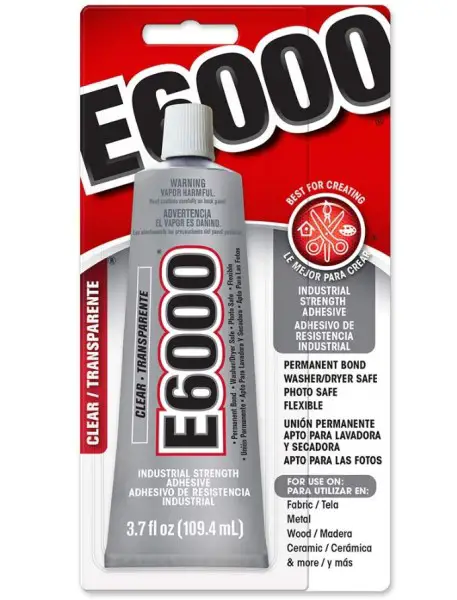

E6000 Glue Overview

E6000 is a glue from Eclectic Products Inc. It belongs to the industrial product line that is specific for heavy duties and works best on materials such as ceramic, glass, wood, and many more.

Nonetheless, household items can sometimes utilize their superb cohesiveness, and your shoes are one of them.

The main component of E6000 is polyurethane of the finest quality. The versatility of this chemical is the key to E6000’s compatibility with various materials.

Aside from its impressive hardness and tensile strength, E6000 is available in several colors that match the finish of most shoes.

Shoe Goo overview

Unlike E6000, Shoe Goo is originally a glue for shoes and not for any other industrial purposes. If you come online and search for shoe glues, you will undoubtedly find this name on the top recommendations.

Shoe Goo can adhere rims and pieces of materials together. Yet they also perform well as a sealant due to the mixture of toluene, styrene-butadiene, and naphtha as a solvent.

Should there be little holes in your shoes and sandals, you can comfortably fill them up with a reasonable amount of Shoe Goo glue.

The most compatible materials with Shoe Goo are canvas, rubber, vinyl, and leather. Another plus point of Shoe Goo is its waterproof and anti-abrasion properties.

It is also not overly rigid once set, so it can handle sporty activities.

Read more: Can You Sell Used Shoes On Stockx? (And Why)

E6000 vs Shoe Goo: Key Differences

The main difference between Shoe Goo and E6000 lies in their purpose.

E6000 targets projects under intense heat, abrasiveness, or impactful conditions, and Shoe Goo is mainly used for footwear and similar items.

How They Work

Despite being glued, the functionality of E6000 and Shoe Goo is very different from each other.

With E6000, you should only use a small drop at a time so you can work with precision because this glue dries and sets extremely fast.

We also recommend putting your gloves on due to the stickiness of the E6000. If you are not careful while using it, you might end up causing a big mess.

On the positive side, the non-flammable property ensures a safe environment for you if your project involves heat.

Shoe Goo, however, is made for shoe repair and protection. You can use Shoe Goo as a sealant rather than a pure adhesive substance. It will fill the tiny pores and leave a shiny finish.

Although it can’t perform well under extreme heat, it has good water resistance. So, your shoes can be exposed to wet conditions without any concern.

How to Apply

E6000 is very suitable for details. When it comes to shoes, you can use E6000 for intricate details such as a small tear or a trail of tiny gemstones.

It’s recommended to apply the glue with a toothpick instead of squeezing a generous amount on your work platform. It’s because this glue can be sticky and dry quickly at the same time.

The usage is simpler because Shoe Goo is made for shoes.

You can use a larger amount on the sole and spread it evenly with a designated tool. After giving it a few minutes to start drying and setting, we will put the sole and the shoe together.

Suitable Materials

E6000 is not the same as Shoe Goo if we are talking about what material to use them on. It works best on surfaces of metal, ceramic, fabric, glass, and rubber, but not on most polymers.

If you are fixing leather, rubber, or vinyl shoes, E6000 would be a great option, for its bond with these materials is very tight.

Shoe Goo has a smaller range of compatible such as leather, vinyl, canvas, and leather because it is not an industrial adhesive.

You can comfortably use Shoe Goo on almost every pair of shoes you have.

Adhesiveness

E6000 is a glue more inclined to industrial uses, thus you can expect it to be capable of enduring extreme heat and weather. Furthermore, it can withstand the test of abrasion, moisture, and UV radiation.

As a domestic glue, Shoe Goo certainly is weaker than E6000, even though it has fairly impressive water resistance. It can be used in unfavorable weather conditions as well as in daily routines.

Do you know: What Does EE Mean In Shoe Size?

How Quick It Dries

Both of these glues are made for immediate purposes, hence they share the same drying time too.

E6000 dry time starts right after you apply it and binds the material fragments together within 2 minutes.

After an extra 10 minutes, the glue will set. The curing phase takes 24 – 48 hours before you can touch and use your shoes again.

Shoe Goo doesn’t lose in terms of drying time either. You apply it and it will begin to dry, set and cure. During the cure time, it’s advisable to leave the shoes without disturbance.

Prices

If we do a quick math on the price per ounce of these glues, Shoe Goo is slightly more expensive than E6000 because of the aforementioned differences.

E6000 was designed to work under harsh conditions, which don’t require much aesthetics, while Shoe Goo can handle more intricate work.

E6000 Glue vs Shoe Goo Pros & Cons

E6000 Pros & Cons

E6000 proves its value when you have cracks and slits to fix. It is compatible with a good number of materials and resistant to heat, impact, and abrasion.

Therefore, you might use it for other projects aside from repairing your shoes.

The downside of E6000 is that once it has cured, there is no easy way to remove the bond.

Secondly, as an industrial glue, the manufacturer didn’t focus on making it smell good. You might need a mask while working with E6000.

Shoe Goo Pros & Cons

Shoe Goo has been on the market for a long time, satisfied customers are the witness for its quality and price.

It can fix any type of shoe and make sure the bond thrives even in wet conditions. The bond is also flexible despite the hardness when it dries.

The hardness is a weakness because it can break under unfavorable conditions. It’s not a good choice if you want an immediate solution either, for it takes at least 24 hours to fully cure.

How To Fix Your Shoe Soles?

Now you have known about the benefits and the drawbacks of the glues in question, it’s time to get your hands dirty.

- You would want to clean the shoe in advance, so you can start your project in a clean state.

- Apply the glue to either the shoe or the sole. If you think using glue on both surfaces gives them a stronger bond, unfortunately, it doesn’t. Excessive glue might smear and take longer to cure.

- Put the two surfaces together right after you’re done spreading the glue. Make sure you press them together nicely and firmly. For more steadiness, use tapes and clamps.

- Leave the shoe untouched for 24 – 48 hours so the glue can cure fully. If you are impatient, the pieces might fall apart again, and we want to avoid it as much as we can!

Final Verdict: E6000 or Shoe Goo?

E6000 vs Shoe Goo is a battle between heavy-duty glue and strong domestic glue.

Shoe Goo is your go-to for most shoe problems since it is not overly expensive or complicated to use, but you still need to give it some time to reach the ideal state.

Meanwhile, E6000 is the big gun when you want to prepare your footwear for extreme conditions.

Ponder upon your situation carefully, and you will be all good!